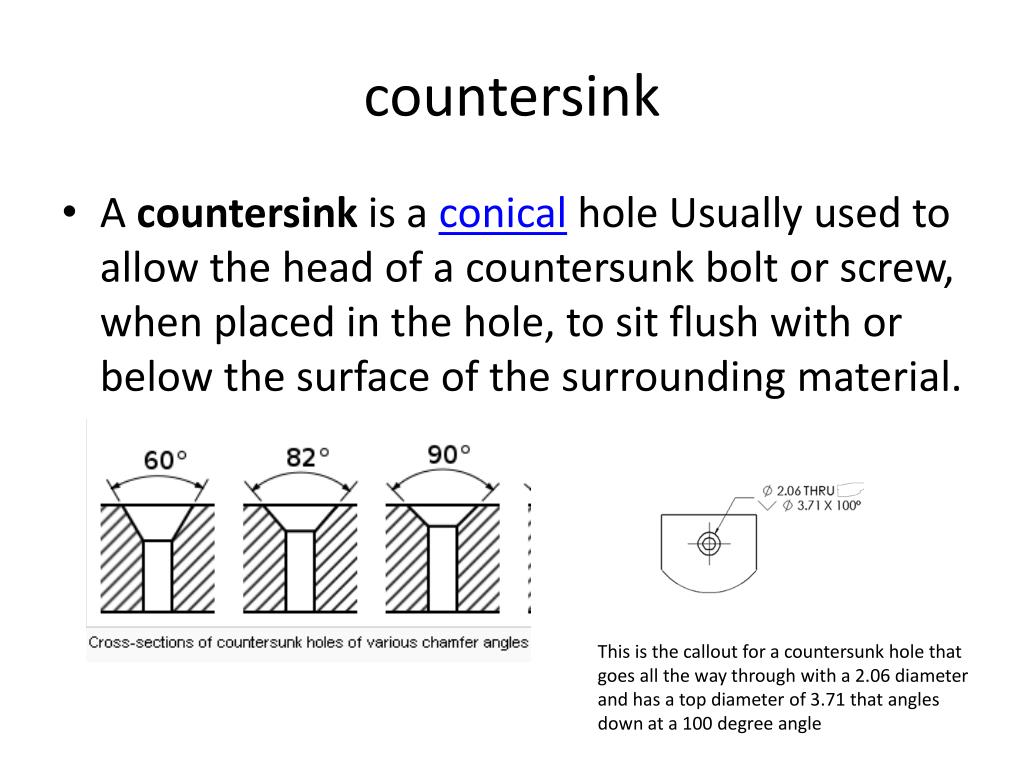

Countersunk Hole Tolerance . In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards to properly call out a countersink hole for manufacturing. Generally speaking, such a tolerance should be: A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. These parameters are crucial in any design of. It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or.

from www.slideserve.com

It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or. Generally speaking, such a tolerance should be: A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. These parameters are crucial in any design of. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards to properly call out a countersink hole for manufacturing.

PPT Holes PowerPoint Presentation, free download ID2107959

Countersunk Hole Tolerance These parameters are crucial in any design of. Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Generally speaking, such a tolerance should be: It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards to properly call out a countersink hole for manufacturing. These parameters are crucial in any design of.

From www.amulettejewelry.com

Clearance Hole Chart amulette Countersunk Hole Tolerance A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals,. Countersunk Hole Tolerance.

From mavink.com

Countersink Chart Countersunk Hole Tolerance In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards to properly call out a countersink hole for manufacturing. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has. Countersunk Hole Tolerance.

From www.youtube.com

Applying Position Tolerances to Countersunk Fixed Fastener Assembly Countersunk Hole Tolerance In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards to properly call out a countersink hole for manufacturing. These parameters are crucial in any design of. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit. Countersunk Hole Tolerance.

From getdrawings.com

Types Of Tolerance In Engineering Drawing at GetDrawings Free download Countersunk Hole Tolerance In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards to properly call out a countersink hole for manufacturing. Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. These parameters are crucial in any design of. It is considered good practice to countersink or. Countersunk Hole Tolerance.

From www.machinistguides.com

Spotfaces All About Machinist Guides Countersunk Hole Tolerance Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or. In this article we’ll define countersink holes, when to use a countersink, and describe how to use. Countersunk Hole Tolerance.

From www.youtube.com

SolidWorks Chapter 5 Drawings (Basic Dimensions and Countersink Holes Countersunk Hole Tolerance Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. Generally speaking, such a tolerance should be: These parameters are crucial in any design of. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. It is. Countersunk Hole Tolerance.

From informacionpublica.svet.gob.gt

Shaft/Hole Tolerances For Clearance Interference Fits Countersunk Hole Tolerance It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Generally speaking, such a. Countersunk Hole Tolerance.

From www.villageinframe.com

M4 Csk Hole Dimensions A Pictures Of Hole 2018 Countersunk Hole Tolerance A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. These parameters are crucial in any design of. A countersink is an angled taper applied to a. Countersunk Hole Tolerance.

From www.slideserve.com

PPT Holes PowerPoint Presentation, free download ID2107959 Countersunk Hole Tolerance Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. These parameters are crucial in any design of. It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or. A countersink consists of a conical hole that is. Countersunk Hole Tolerance.

From www.7pcb.com

The Difference Between Counterbore and Countersink Holes Countersunk Hole Tolerance It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. These parameters are crucial. Countersunk Hole Tolerance.

From saayarelo.com

SOLIDWORKS 2018 Agujero y Calado Avanzado Tutorial Innova Systems Countersunk Hole Tolerance A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat. Countersunk Hole Tolerance.

From pacchlist.weebly.com

Iso 2768 hole tolerance table pacchlist Countersunk Hole Tolerance It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle of the cone is determined by the fastener to be used. In this article we’ll. Countersunk Hole Tolerance.

From engineersbible.com

Countersunk Hole Size for Socket Flat Head (ANSI Metric) Countersunk Hole Tolerance A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. These parameters are crucial in any design of. Generally speaking, such a. Countersunk Hole Tolerance.

From www.scribd.com

CounterSink Holes Chart PDF Engineering Tolerance Screw Countersunk Hole Tolerance Generally speaking, such a tolerance should be: A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards. Countersunk Hole Tolerance.

From www.scribd.com

Tech Iso Tolerances H13 PDF Engineering Tolerance Applied And Countersunk Hole Tolerance Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. Generally speaking, such a tolerance should be: In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards to properly call out a countersink hole for manufacturing. These parameters are crucial in any design of. A. Countersunk Hole Tolerance.

From www.villageinframe.com

Metric Countersunk Hole Dimensions A Pictures Of Hole 2018 Countersunk Hole Tolerance Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or. A countersink consists of a conical hole that is coaxial to a cylindrical hole, where the angle. Countersunk Hole Tolerance.

From www.linkedin.com

The difference between "countersunk hole, through hole, blind hole" Countersunk Hole Tolerance These parameters are crucial in any design of. In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards to properly call out a countersink hole for manufacturing. A countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit. Countersunk Hole Tolerance.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The Countersunk Hole Tolerance These parameters are crucial in any design of. Generally speaking, such a tolerance should be: In this article we’ll define countersink holes, when to use a countersink, and describe how to use ansi common standards to properly call out a countersink hole for manufacturing. Occasionally, a countersink is used simply as a method of chamfering or deburring a hole. A. Countersunk Hole Tolerance.